Best Surfaces implements Siti B&T group technology furthermore

Best Surface: SITI B&T is our strategical technological partner in Spain to produce mineral stone

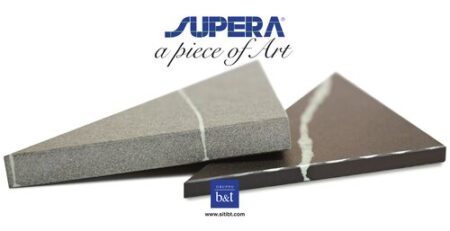

SITI B&T Group consolidates its technological partnership with Best Surface, known for its Idylium brand, a manufacturing company that innovates the world of design and architecture with its mineral stone for tops and interior and exterior surfaces. SITI B&T has made all its complete technological solutions available to Best Surface, starting with SUPERA® technology, creating a “turnkey” plant for large sizes of mineral stone in Castellón, Spain. Elegance and refinement, with unparalleled aesthetic effects, are the salient features of a product that best interprets Italian style, entirely conceived in Milan, the world capital of fashion and design.

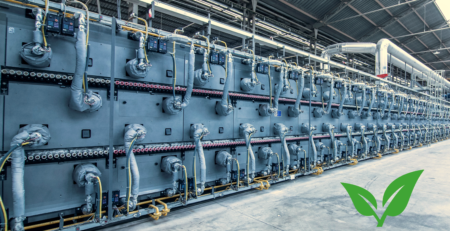

It is one of the most prestigious and recent achievements of SITI B&T, a complete plant to produce large slabs for interior design. The line brings together numerous technologies that satisfy a concept of Total Environmental Respect (T.E.R.), production processes with minimal environmental impact.

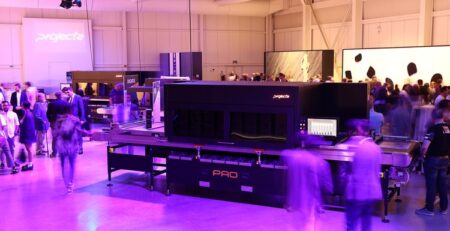

Best Surface uses the technological solutions of SITI B&T Group (which include Projecta Engineering’s digital decoration and Ancora’s finishing) for each phase in the production process. Technical and aesthetic know-how that the Italian group can offer, starting with the creative and planning contribution of Digital Design, a company dedicated to creating graphic projects.

The Idylium production plant in Castellón spreads over a total area of 40,000 square meters. The plant produces four different sizes of slabs: 1600×3200, 1200×2600, 1200×2400, 1000×3000 with thicknesses ranging from 6 to 30 mm.

SITI B&T has provided technological solutions for each phase of the process. From powder mixing and feeding systems to technologies for creating full-body aesthetic effects (through veins), SUPERA® is pressing (from 36,000 tons), equipped with the Start & Stop® energy-saving system. The power on demand hydraulic generator reduces energy consumption by up to 30% and the Ancora technology for green cutting for slabs.

The multi-level horizontal dryer feeds Projecta Engineering’s Full Digital decoration line, with the INNOVA printing machines, both for the application of glazes and for the printing of graphics, expandable up to 16 colors, as well as the INNOVAFIX dry printing machine for the application of grits and material effects.

The Titanium®double-channel kiln for slabs, best in class for energy efficiency and lower emissions, guarantees a reduction in consumption of up to 30% and productivity that is 25% higher than alternative solutions.

The line is SITI B&T fitted out with a latest-generation sorting and palletizing system, equipped with a Gripstrong storage system. There are also artificial vision machines for the control of planarity and size.

A completely configurable LGV supervision technology then manages internal handling of the slabs with Totally Safe Mobility (TSM) operator safety sensors, which contains the flows of materials output from the kiln to the sorting line and from the temporary storage of the product to the finishing phase.

The slabs are stored on stackable layers up to 6 levels by 4 Big Mover laser-guided vehicles (LGVs).

The plant entirely fits in with the topics related to the smart factory, from a perspective of totally interconnected systems. It is equipped with the bt-TUTOR plant supervisor, which monitors, collects data, and controls the plant, interacting with production planning, preventive and predictive maintenance, as well as being cloud compatible, supporting mobile devices, and having a user-friendly operator interface.

Still in Spain, on the finishing front, Ancora technologies have been chosen by Polialc, a company based in the Castellón district specialized in squaring, lapping, and cutting, for all the slab finishing phases.

The size output is from a minimum of 1000×1000 mm up to 1800×3600 mm. With thicknesses from 5 mm up to 30 mm, with the functions of surface lapping and polishing full-body products.

With full-body decoration and 3D surface structures that Supera®, the possibilities are infinite. Continuous research has allowed us to obtain innovation patents even in full-thickness decorations to create original surfaces with a strong identity. The reinvented material with three-dimensional and “through” effects throughout the mass. A technology capable of creating beauty.

Some of the effects obtainable:

VENA 3D full-body veining combined with digital decoration

CEMENTO 3D micronized powders, and double loading

TUTTO3D full-body decoration

SUPERA® can create high reliefs with extraordinary depth, up to 4 mm deep on very thick slabs, and unparalleled definition.

SITI B&T is a group that thoroughly covers the value chain, with proprietary technology. Each phase of the production process finds a specialist within the group: SITI B&T (complete lines for ceramics), Projecta Engineering (full digital decoration), Digital Design (creativity and design), Ancora (complete finishing systems), Diatex (diamond tools).