The first complete Supera® line in Iran

Rock Sanat chooses SITI B&T for the large slabs

Formigine, November 2019 – SITI B&T opens the large slab market in Iran. The Formigine group has installed a complete Supera® line at the Rock Sanat ceramic company, one of the leading producers in the Middle Eastern country. Production at the Tehran plant started at the end of August.

Formigine, November 2019 – SITI B&T opens the large slab market in Iran. The Formigine group has installed a complete Supera® line at the Rock Sanat ceramic company, one of the leading producers in the Middle Eastern country. Production at the Tehran plant started at the end of August.

Thanks to complex research and development work carried out by SITI B&T technicians on the pilot line at the bt-LAB, the technological research and development centre located in Formigine, the newly installed line has a very high tolerance to the variability of raw materials. This latter feature makes it possible to use local raw materials, at zero km: an aspect that has a positive impact not only on an economic level by reducing direct production costs, but also on the industrial one, using traditional mixes for standard sizes.

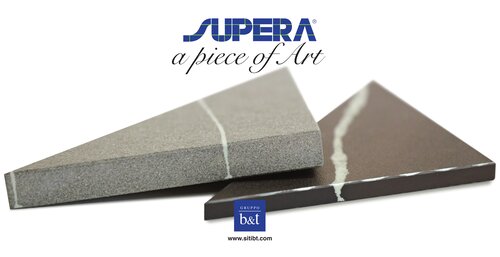

The Supera® pressing system and the XXL kiln (with a 3850 mm opening and the possibility of firing two slabs side by side simultaneously) will allow the production of the largest porcelain stoneware slabs ever made in Iran, up to a size of 1600×3200 mm.

A technological revolution that also allows Rock Sanat a rapid size changeover, going from 1600×3200 mm to 1200×2400 mm. In light of this experience, SITI B&T has thus also developed a range of Supera® models with lower tonnage for the production of more traditional ceramic sizes, maintaining a high productivity (six pieces 1220×1200 mm per minute) with the advantage of pressing on belt and not on mould: “Supera HP” model.

No wastage (max 1.5 mm per side), 2 tenths of a millimeter of thickness variation on the long side are other features that make the Supera® line among the most cutting-edge production solutions in the ceramic field.

A focus not just on the technical qualities but also on environmental impact. The Iranian manufacturer has indeed benefited from the know-how of SITI B&T to develop the energy saving concept thanks to technology such as the Start&Stop system, the innovative “power on demand” hydraulic control unit that reduces energy consumption by up to 30% and, by not heating the oil, saves additional kW for cooling.