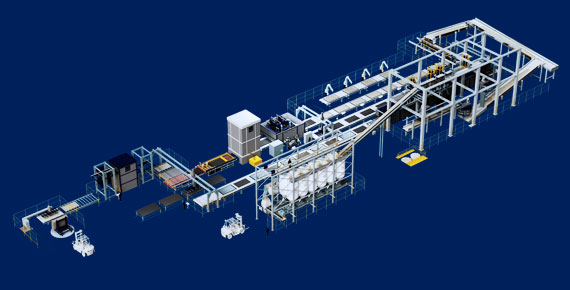

The B&T Quartz division, entirely dedicated to design and production of complete systems for agglomerated quartz slabs,was created to respond to the growing demand for differentiation and innovation in the agglomerated stone market

In particular, the B&T Quartz division designs and manufactures plants for the production and digital decoration of slabs, available in different configurations to meet different customer needs in terms of production capacity, product characteristics, and capital investment.

B&T Quartz provides its customers with tailor-made solutions with the most innovative systems and technologies applied to the quartz industry, such as:

- High productivity of the plant

- World-class energy saving systems

- No deep and expensive foundations are required for the press, therefore reduced times and investments

- No transmission of vibrations to buildings and workers within the plant

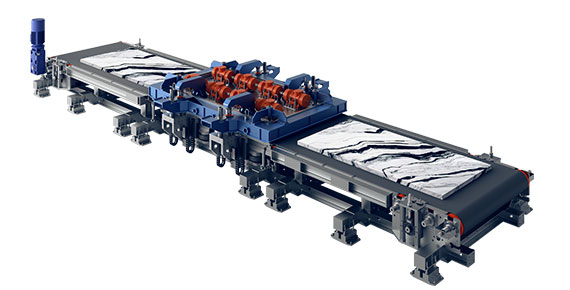

SLABS FORMING LINE

The bt-TWIN® patent is a double vacuum vibro compression technology that allows for energy savings and faster compaction without the need for expensive reinforced concrete foundations.

bt-TWIN® guarantees perfect consolidation of the slabs and provides better vibration damping, avoiding transferring them to objects and people present inside the system.

Thanks to the absence of foundations, it is also possible to easily reposition the press and modify the line.

SLABS DIGITAL DECORATION LINE

The first printing process on quartz slabs in the category, which allows to design new unique products not yet on the market.

With the Q-Art Line, the B&T Slab Digital Decoration Line and Q-Plotter® it is possible to reassess even the second grade quartz slab, printing on it the most refined marble/stone graphics and sell ita s a premium slab.

The B&T Quartz division provides its customers with exclusive graphics with innovative and exceptional motifs, thanks to Digital Design, the Group’s graphic design company.